Ventajas

- Alta tasa de reutilización de materiales

- Velocidad de instalación general rápida

- Movilidad horizontal general del encofrado, con menor intensidad de mano de obra y un entorno de construcción más seguro;

- Alto valor residual de aleación de aluminio.

- Respetuoso del medio ambiente

Flujo de Instalación del Encofrado

Trabajo de preparación: Preparar el plano de diseño para la instalación y otros equipos relevantes, incluido el cinturón de seguridad y otros, así como la configuración del sitio de instalación del encofrado.

Paso 1: Utilice una grúa torre para levantar y colocar la cercha sobre un travesaño y conecte el otro lado de la cercha con un par de tirantes de tijera. A continuación, instale las tablas de conexión, los pernos y otros accesorios para fijar el cuerpo del armazón.

Paso 2: Instalar la parte de extensión del marco del encofrado. Utilizar pernos, segmentos, puntales de puntal y otros accesorios para fijar las tablas de conexión a un muro multiusos, logrando así la extensión del cuerpo del marco.

Paso 3: Instale la parte de la viga de aluminio. Fije la viga de aluminio en la ranura correspondiente. A continuación, instale la viga de aluminio mientras utiliza una abrazadera para fijarlas de forma correspondiente.

Paso 4: Instalar la parte del encofrado, Colocar el encofrado de madera sobre la viga de aluminio y fijarlos con remaches (Tener en cuenta que el encofrado debe colocarse en ángulo recto con respecto a la viga de aluminio)

Paso 5: Instalar la parte del pasamanos, para conectar y fijar el pasamanos a la pared multiusos.

Paso 6: Ajustar la verticalidad del encofrado antes de realizar el hormigonado in situ.

Aplicación: Construcción de pisos de concreto colado in situ de grandes bahías y gran profundidad para edificios de gran altura.

Efficient Slab Construction with Table Formwork Systems and Beamless Floor Solutions

In modern construction, the table formwork system has become an essential solution for efficient and high-quality slab casting. Especially popular for creating beamless floors, this method allows for flat, smooth concrete surfaces without the need for traditional beams, offering both architectural flexibility and faster construction times. The table formwork for slab is designed to be reusable and easy to assemble, which significantly reduces labor costs and improves project efficiency.

Durable Steel and Truss Table Formwork Systems Enhancing Construction Efficiency in Malaysia

In Malaysia, steel formwork Malaysia suppliers provide durable and reliable materials that withstand repeated use, ensuring consistent quality across multiple projects. Among various options, the truss table formwork is highly favored due to its robust support and ability to span large areas without additional props. The table form formwork combines strength and adaptability, making it suitable for a wide range of building designs.

Overall, the table formwork system streamlines the construction process by enabling rapid installation and dismantling while delivering superior structural performance, especially for beamless floor applications.

Leading Table System Formwork Solutions: Quality and Innovation from Malaysia’s Geto Factory

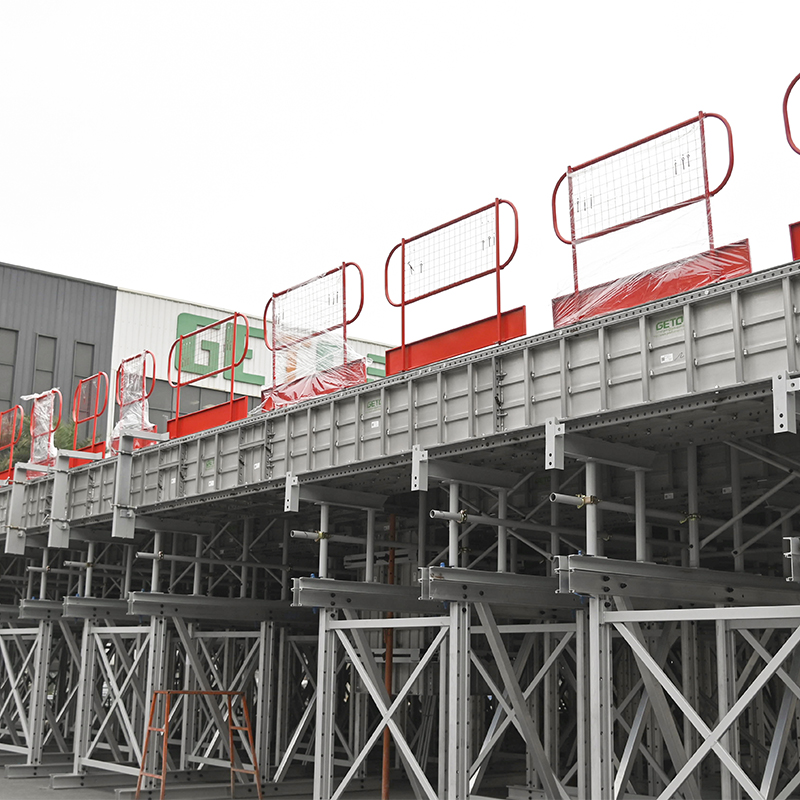

The table system formwork has become a cornerstone in modern construction, offering efficient and reusable solutions for slab casting projects. As a leading table formwork exporter, many manufacturers ensure high-quality products tailored to meet international standards. In Malaysia, the Geto Formwork Factory (Nilai) stands out as a premier system formwork supplier, specializing in producing durable and precise assembled table formwork factories that serve both local and overseas markets.

Streamlining Construction with Table Formwork and Aluminium Solutions from Geto Malaysia

The table formwork construction process is streamlined by the use of table form shuttering or table shuttering, also known as tabla formwork or tabla shuttering in some regions, providing strong, safe platforms that accelerate project timelines. Whether called tableform formwork, table form work, or simply formwork tables, these systems are designed for quick assembly and disassembly, reducing labor costs and improving site safety.

Additionally, for projects in Singapore, aluminium formwork Singapore offers lightweight yet robust alternatives that complement traditional table shuttering methods. Overall, choosing a reputable formwork company in Malaysia like Geto ensures access to high-quality products and expertise, supported by comprehensive documentation and even Geto Formwork Factory (Nilai) photos showcasing their advanced manufacturing capabilities.